Multi-axis Measurement

Rotary Indexers

MicroTheta Rotary

The MicroTheta™ Rotary brings true fourth axis measuring capability to OGP dimensional measurement systems.

- Automatically rotate parts to present a different view to the measuring system, with no need to re-measure datum features

- OGP 3D metrology software includes rotary axis calibration routines to locate the rotary in 3D space

- MicroTheta Rotary may be mounted horizontally or vertically, per application requirements

- Pair the MicroTheta Rotary with other OGP rotaries to add a fifth axis of rotation

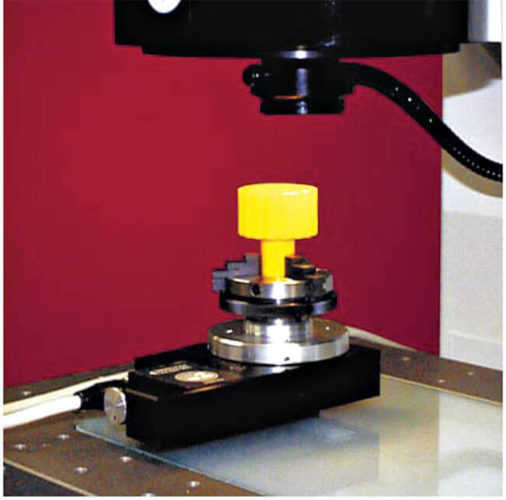

Miniature Servo Rotary

The Miniature Servo Rotary (MSR™) is a compact angular positioning device. Tightly integrated with OGP metrology software, MSR offers mounting flexibility in orienting the rotational axis.

- Automatically rotate parts to present a different view to the measuring system, reducing the need for multiple part setups. Part rotation can be a step in OGP metrology software measurement routines, eliminating the need to manually refixture a part

- Mounting bracket allows horizontal or vertical axis applications

- Combine MSR an MTR or a second MSR to provide rotary motions in two perpendicular axes

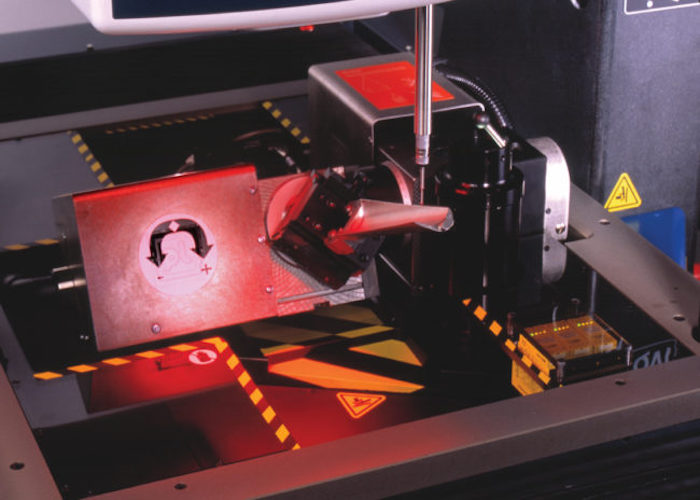

High Precision Rotary

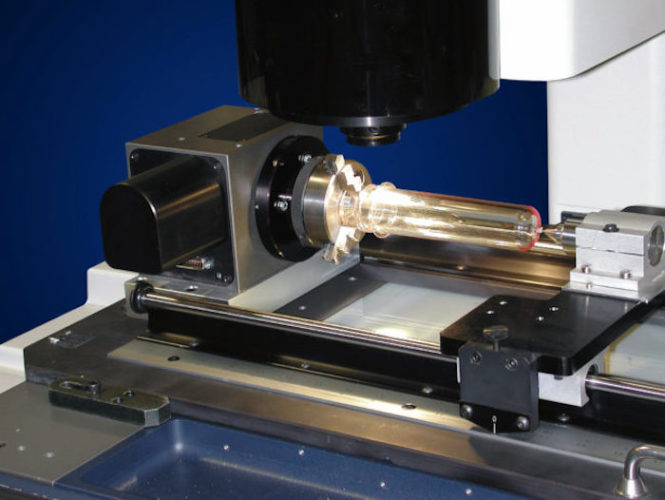

The compact HPR-2000 Rotary High Precision Air-Bearing Rotary Indexer provides high accuracy airbearing fourth axis measuring for OGP dimensional measurement systems. HPR-2000 Rotary offers:

- Precision air bearing spindle, powerful direct drive DC servo motor, and a precision ruled rotary encoder offer high accuracy, yet the spindle can rotate a full revolution in less than 8 seconds

- OGP 3D metrology software can rotate the rotary-mounted part coordinate reference system in 3D space to maintain datum and measurement integrity

- Can be mounted horizontally or vertically, or may be paired with an OGP Heavy Duty Rotary (HDR) for a 5th axis of rotation

Heavy Duty Rotary

The Heavy Duty Rotary (HDR) is a machine tool type rotary designed to hold heavy parts up to 30 kg-cm. It brings true fourth-axis measurement to select floor model SmartScope® systems equipped with ZONE3 metrology software. With the HDR, parts may be automatically rotated during the measurement routine to present practically any view to the system, without the need to re-measure datum features after rotation.

Rotary axis calibration routines locate the rotary axis in space and correlate all feature measurements to it and the XYZ axes of the measurement system. Relational measurements between features measured at different rotary positions are easily determined by simply picking the features from the software’s interactive model.

The Heavy Duty Rotary (HDR) Dual Rotary stage provides true 4th axis control, eliminates multiple fixtures, provides one origin setup for all features, measures complex geometries, and measures features on any compound angle and measures turbine blades, injectors, complex prismatic parts, etc.

The HDR rotary can be paired with an MTR or second HDR rotary to add a fifth axis of rotation.

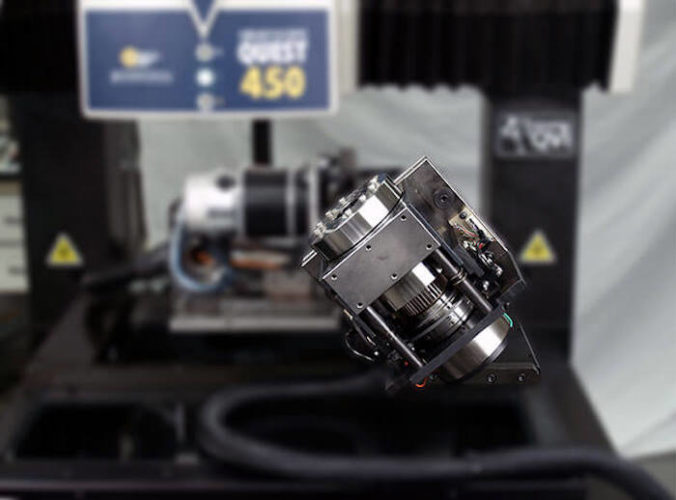

Dual Rotary Indexers

Mount two rotary indexers together with their axes perpendicular to one another to add two more axes of part positioning to select SmartScope® systems.

The part under inspection is attached to the secondary rotary, which is mounted to the primary rotary. The part can be rotated in two different axes to provide a means of bringing features with compound angles into the line of sight of the optical sensor axis and within the reach of available laser sensors or touch probes for measurement.

Several combinations of rotaries can be configured, depending on the application and the available measurement envelope of the machine.

Download Assets

© 2016-2025 D. Beck Company LLC