Tactile Probes

Access features that are difficult with just video measurement alone.

REQUEST A QUOTE

Tactile Measurement

Tactile Probes

Articulating Probe Head

The PH10 PLUS are a family of motorized articulating probe heads that allows for automatic reorientation of the tool, increasing throughput and eliminating the needs for multiple probe configurations.

The three different models each can carry a range of probes and other accessories reducing the need for reorientation of the part or time-consuming tool changes from a change rack. The heads can be oriented in up to 720 different repeatable positions, allowing direct access to most features.

The PH10T and PH10M are mounted on air deployment mechanisms to automatically deploy and retract the entire head when not in use. The PH10MQ is a variant of the PH10M that allows the head to be attached directly to the quill of a CMM.

All are controlled through the PHC10-3 PLUS head controller which integrates seamlessly with OGP systems.

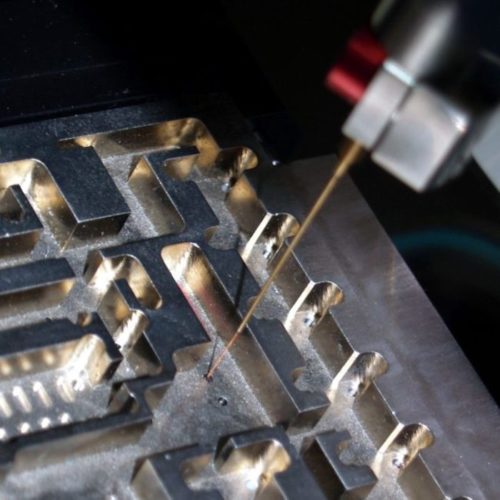

Feather Probe

Feather Probe™ from OGP provides access to small features that are inaccessible to video measurement or conventional touch probes, or too sensitive to withstand traditional probing forces, by using a specific sensing technology to determine when a resonating stylus has come close enough to a surface to dampen its resonance. This sensor can acquire a data point with only milligrams of force making it perfect for fragile components.

With available styli as small as 0.100 mm, Feather Probe is able to access minute features inaccessible to traditional touch probes.

Mounted on a motorized deployment mechanism, the stylus is automatically deployed and retracted to a safe location when not in use.

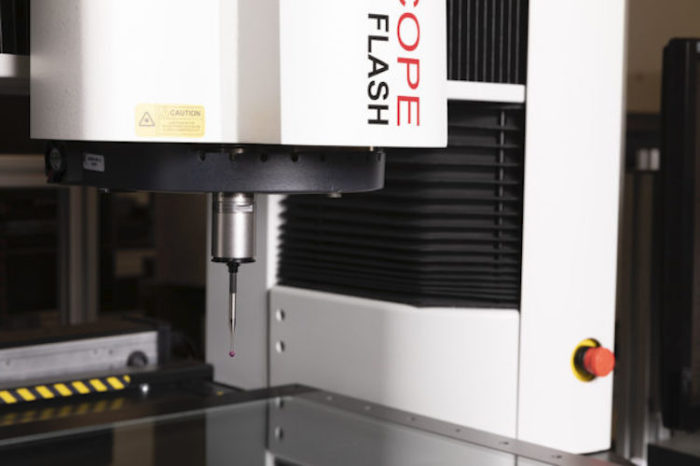

Scanning Probe

Add contact contouring capability to your OGP system with the SP25M scanning probe. Easy to use, simply select a start and end point and the scanning probe follows the part profile between those points.

Using intelligent algorithms, ZONE3® metrology software drives the probe, rapidly following the part contour and collecting data points at a user-defined velocity and data sampling rate. The scanning probe automatically adjusts point density when the probe is rounding curves. Both programming and measurement times are greatly reduced compared to single-point probing.

Scanning probes on SmartScope systems are mounted in fixed positions offset from the optics and can optionally be incorporated with automatic deployment mechanisms and articulating heads on select systems.

Optional change racks allow for different probes to be automatically exchanged within a program without any operator intervention. Kinematic mounts allow for change racks to be taken on and off without the need to relocate afterwards.

Touch Probe

Single point touch trigger probing extends measurement versatility of measurement systems from OGP. Using a touch trigger probe, you can measure features that are difficult to image, or surface boundaries that are inaccessible to video.

Touch probe measurements can be part of any ZONE3® or Measure-X measurement routine. A unique probe-to-optics offset calibration with an included certified reference sphere ensures that all sensors are referenced to the same coordinate system so measurements can use points from any sensor.

Touch probes are mounted in fixed positions offset from the optics and can optionally be incorporated with automatic deployment mechanisms and articulating heads on select systems.

Optional change racks allow for different probes to be automatically exchanged within a program without any operator intervention. Kinematic mounts allow for change racks to be taken on and off without the need to relocate afterwards.

Download Assets

© 2016-2025 D. Beck Company LLC