Optical Sensors and Accessories

Modern advancements in camera and optic technology makes video measurement a pragmatic choice when considering a multisensor metrology solution that is both fast and accurate.

REQUEST A QUOTE

Fast and Accurate

Optical Sensors and Accessories

Zoom Optics

Fast, non-contact video measurement provides high accuracy and repeatability for defined dimensions.

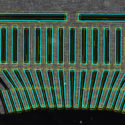

Video sensors on OGP SmartScope systems consist of high resolution metrology cameras, a motorized zoom lens assembly, and variety of front objective and add-on lenses. Additionally, the AccuCentric assembly mounts to zoom lens assembly and contains an LED reticle that is used to automatically recalibrate the optics whenever you change magnification.

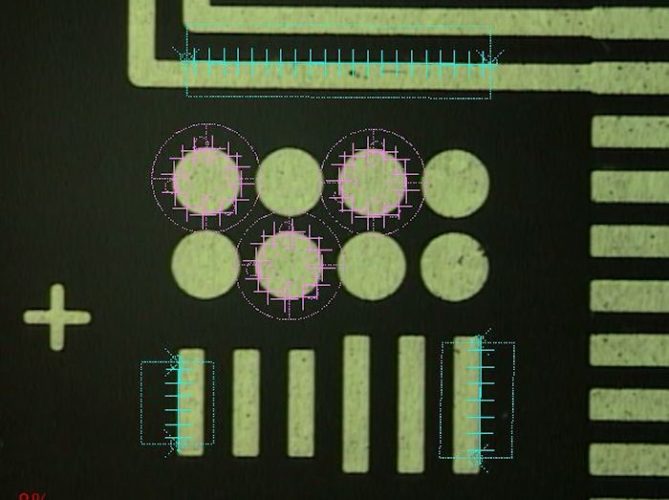

What sets OGP apart is the ability to take the captured images from these advanced video sensors and combine them proprietary edge detection and autofocus algorithms available exclusively in OGP metrology software packages. Tools such as:

FeatureFinder – Used to find the edge of a line, circle, or arc quickly and easily

FeatureExtractor – Automatically identifies features and performs quick measurements between auto-identified features

Weak Edge – Used to find a point on a low-contrast, rough, or ragged edge

Strong Edge – Used to find a point on a high-contrast, smooth edge

Advanced Edge – Used to find the edge of a line, circle, or arc using advanced edge analysis

Edge Trace – Used to measure many points on a line, arc, circle, or irregular contour

Focus – Automatically focuses a feature for very precise Z-axis measurement

Area Multi Focus – Performs a surface profile analysis by automatically focusing the video image across multiple patches within the area of interest

Extended Depth of Field Imaging (EDFI) – Image acquisition graphic divided into a grid during an autofocus producing a combined single flattened image

Centroid – Finds the perimeter or center of an irregular feature or blob

Blob – Identifies groups of adjacent pixels of the same color against a contrasting background

Fixed Optics

Benchmark, Pinnacle and Summit systems may be configured with either the Single Magnification Fixed Lens Optics, or the unique Dual Magnification Optics system. Both of these arrangements offer optical interchangeable front objective lenses to allow the magnification and field of view size to be matched to the features being measured.

The single magnification system is simple and offers an optical resolution that is well matched to the megapixel digital camera with the standard objective lenses. This system is ideal for high-speed measurement of parts with many similar features, for which a single magnification is sufficient.

The dual magnification system utilizes two integral optical paths, each with its own camera. The high magnification path is a 4X multiple of the low magnification, offering an instantaneous zoom capability for higher optical resolution. This system is ideal for measurement of parts where both a wide field of view and high accuracy are desired for different features. The dual magnification system is also ideal for applications requiring the best autofocus performance.

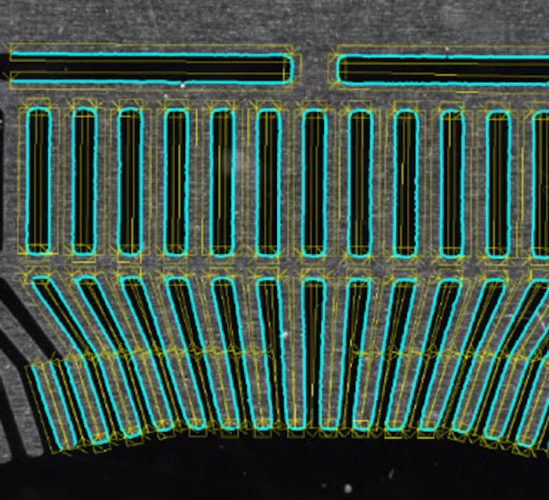

Fixed optics systems offer exclusive technologies such as Area Multi Focus (AMF) and Continuous Image Capture (CIC).

AMF creates a high-resolution 3D data set from a normal autofocus pass, offering a high-throughput alternative to single-point laser surface scanning. An Extended Depth of Field Image (EDFI) can also be simultaneously created to provide an image that is completely in focus through the field of view. AMF and EDFI are available in VMS and ZONE3 metrology software.

CIC synchronized illumination with camera frame acquisition and stage movement to acquire video images non-stop. For components with densely packed features, throughput improvements of 50% to 200% are typical, compared to standard move and measure techniques. CIC is available in VMS and Elements metrology software.

Grid Projectors

Many surfaces (such as glass, clear plastic, and mirror-like finishes) create images with extremely low, or worse, nonexistent contrast. A Grid Projector accessory from OGP measures these surfaces.

The Grid Projector works by projecting a grid pattern onto the surface of the part from behind the front objective lens using an LED source. The system is designed so that the image of the grid will only appear in focus when the surface of the part is exactly coincident with the focal plane of the optics.

The autofocus routine can then use the contrast contained in the grid image just as if it were present in the surface of the part and since the autofocus algorithm is finely tuned to the characteristics of the grid image, repeatability is significantly improved.

Grid Projectors are available on Fixed Optics and most SmartScope systems.

SmartRing Light

SmartRing light illuminators accomplish difficult tasks by providing light that is programmable for both direction and incidence angle

Consisting of six or eight concentric LED ring lights, the inner rings illuminate the part from above, almost “square on.” The outer rings provide oblique lighting, ideal for chamfered edges and blended radii. By selecting different rings, you control the angle of incidence of the illumination.

Each ring is also divided into eight sectors, allowing you to specify the direction of the light. Using SmartRing’s graphical interface, you can select any combination of rings and sectors to create just the right illumination for any application.

Available on OGP video and multisensor systems SmartRing lights measure even the most difficult parts with ease. If you’ve got a tough non-contact measurement application, take a close look at SmartRing. It’s the right light for the right measurement.

Programmable Ring Light

The Programmable Ring Light (PRL) offers the ability to automatically change the angle of incidence and color of illumination in addition to intensity and direction of illumination.

Red, green, and blue LED’s are arranged symmetrically in four quadrants to provide multiple colors of illumination for part measurement. All three colors can also be combined to provide an additional white light source.

The light is directed through parabolic mirrors to redirect towards the surface of a part. The PRL height in relation to the part can be automatically adjusted to change the angle of incidence of the illumination from up to 75° down to 10°.

Fixed Optics are specifically designed to work with the PRL. All lenses are parfocal so as the PRL moves through its range, the angle of incidence remains the same for the same programmed positions of its mirrors, regardless of the lens.

Multicolor PRL’s come standard on Benchmark, Pinnacle, and Summit systems with all green, blue, and white versions available for applications where multiple colors are not needed and a greater single color intensity is desired.

© 2016-2025 D. Beck Company LLC